IFPL is a specialist electronics manufacturer with a reputation earned over more than 25 years in the aerospace industry.

Traditionally focusing on the design and manufacture of bespoke audio and power products, we also offer our capabilities to the broader market as a sub-contract partner. We provide services from initial concept and prototyping to complete manufacturing and logistics, all from our facility on the Isle of Wight, UK.

IFPL provides expert product design support from concept development and process optimisation through to prototyping, manufacturing, and delivery

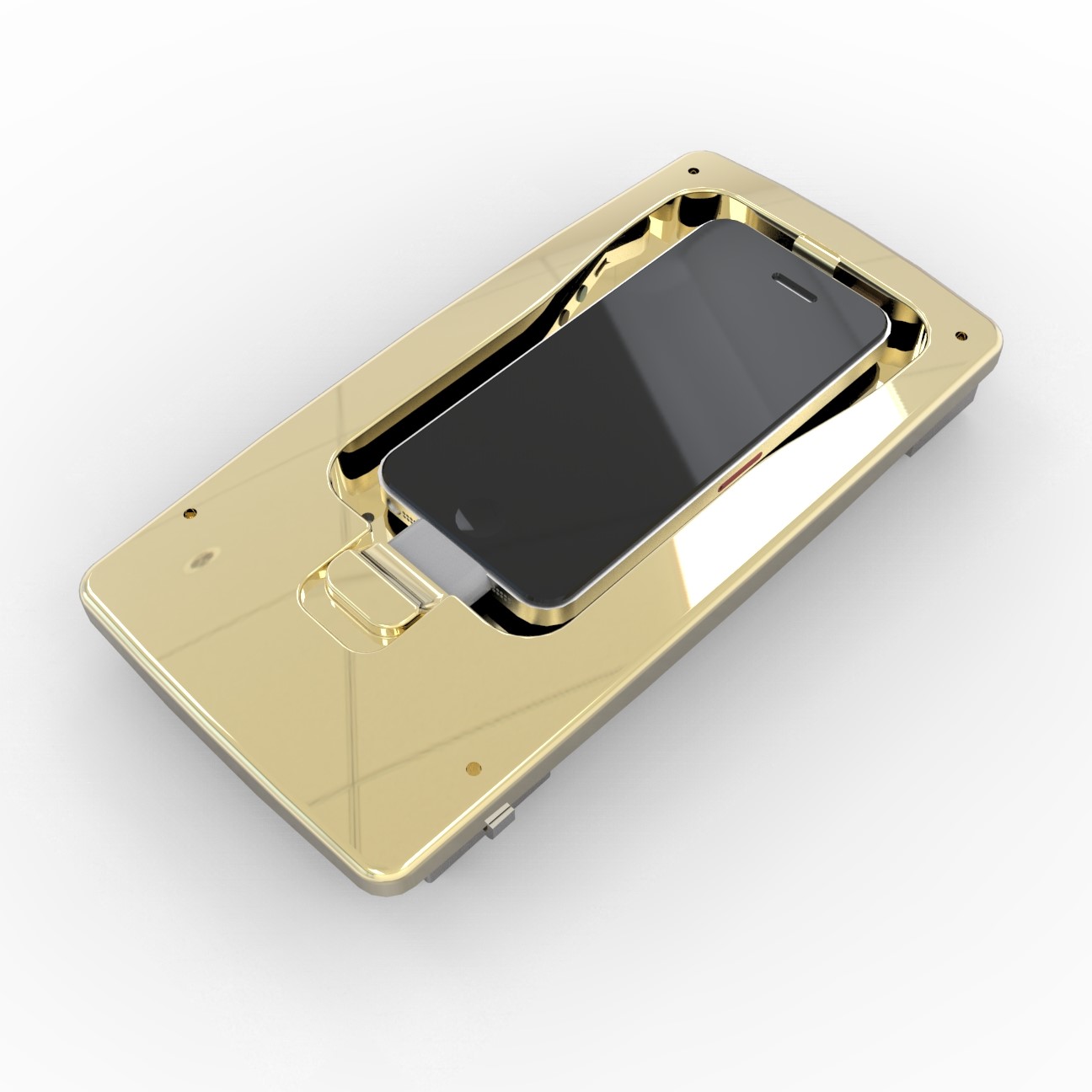

Our design team is adept at using innovative methods to overcome product space constraints and address the challenges of cost, manufacturability, repeatability, and reliability.

Our highly qualified team of mechanical, electronic and production engineers utilise a wealth of experience across the aviation, civil and defence industries to provide collaborative support to a global client base. We can provide expertise in power delivery, data, and wireless communications systems, along with proven design capabilities in plastic injection moulding and ultrasonic welding.

From initial consultation to preliminary designs and visuals we apply our extensive knowledge alongside a range of CAD and simulation tools, including circuit simulation, to develop the perfect solution to any brief.

Utilising our onsite laboratory, fully equipped with EMC chamber and 3D printers, we support rapid prototyping to efficiently turn design concepts into pre-production prototypes.

We conduct a comprehensive test programme, prior to production readiness, to ensure the design is fully documented, qualified, and meets the specification and regulatory standards required.

IFPL delivers through-life customer service and support for all our products to help our customers resolve any start-up issues, and work with them should they require any improvements or upgrades.

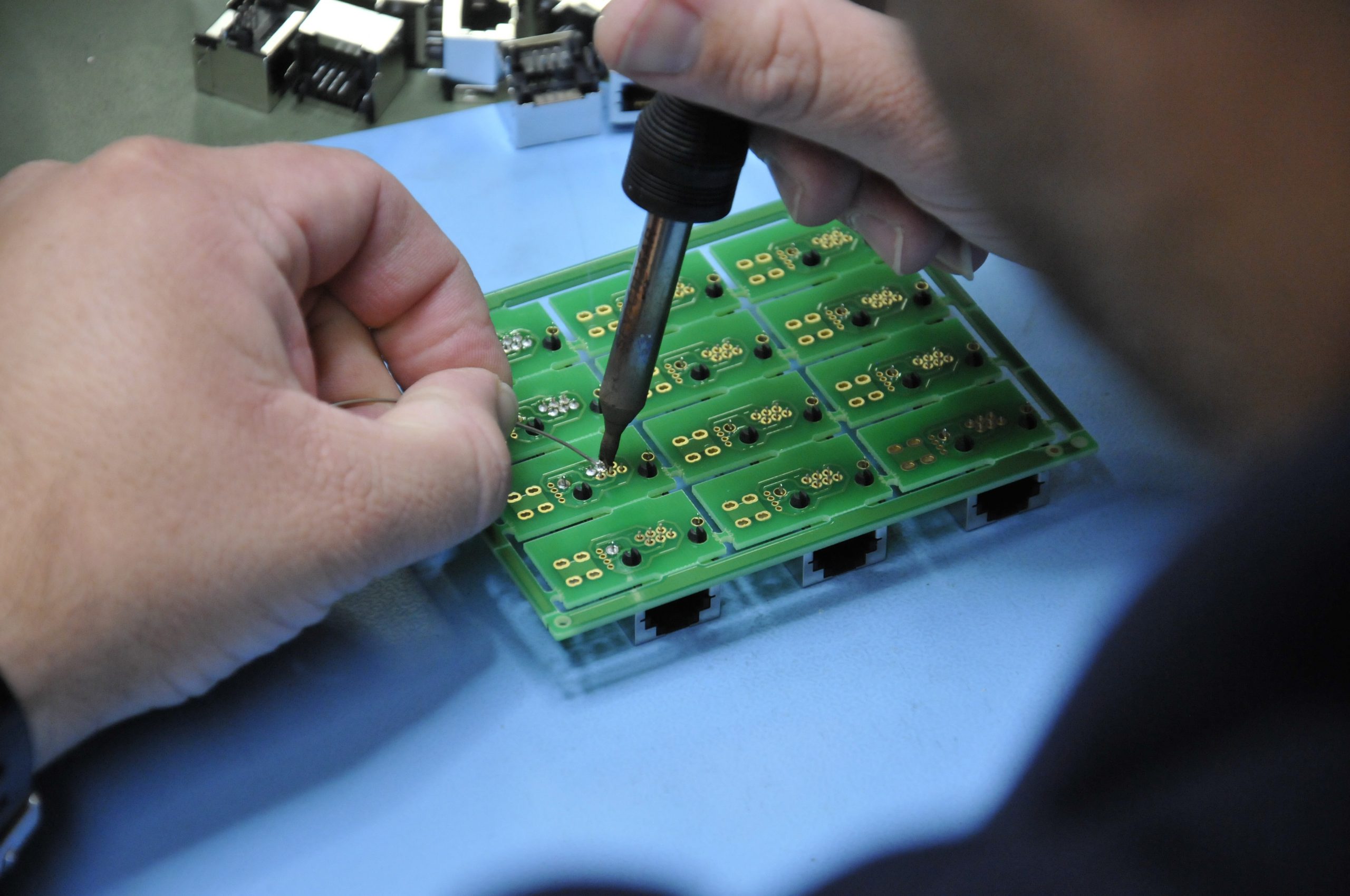

With an IPC accredited team and an award-winning UK manufacturing facility, IFPL is equipped to meet a variety of your production requirements, from electronics design, manufacture and box builds, to a full turnkey solution including material sourcing and logistics.

At IFPL we have embedded lean manufacturing systems into all aspects of our processes, ensuring the most efficient methods are used to build your products on time and to the highest standards. Our manufacturing team are adept at optimising production cells to best utilise our experience and skills in PCBA manufacture, circuit & cable assembly, ultrasonic welding, manual processing, and rapid prototyping.

Our highly skilled team can operate to IPC Class 3 for your PCBA and cable harness requirements.

Applying our industry knowledge and manufacturing capability, we can accommodate requirements of varying complexity, built to your specification, ranging from first-offs to mass production.

IFPL can undertake a variety of processes using dedicated assembly lines equipped for adhesives, mechanical fixing, snap-fit as well as exceptional ultrasonic welding facilities.

We employ ESD protection measures, 5S and Continuous Improvement systems throughout our production facility, ensuring an efficient, clean and safe environment to build the highest quality products.

Inspection and test are performed in agreement with our customers’ requirements, and in accordance with our CAA Part 21G and AS9100D approvals. We can provide first article inspection (FAI) reports where needed.

Our highly trained team has access to an on-site metrology lab and resources including:

Working closely with our suppliers and specialised local sub-contractors, IFPL has established a robust strategic supply chain network to provide a cost-effective and sustainable turnkey solution. We can accept free-issue materials through to providing fully traceable material sourcing on complete or partial kits.

Our dedication to continuous supplier development and logistical forward planning ensures a seamless process from scheduling through to product delivery.

We provide:

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |